Development & Testing

Accelerating Time-to-Market

Our commitment to innovation is backed by the most advanced engineering tools enabling us to accelerate innovation.

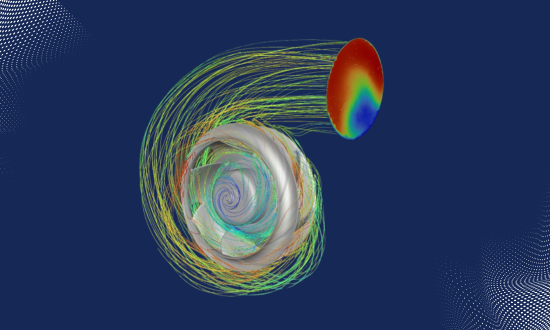

- Our expertise extends to structural and tolerance analysis, utilizing tools like Abaqus FEA, COMSOL, and CETOL 6σ to optimize strength and performance.

- We conduct fluid flow simulations with CFdesign and COMSOL, while magnetic circuit simulations rely on Flux 3D and gear design simulations with SimWise 4D and KISSsoft.

- We utilize state-of-the-art design & development tools for in-house electronics hardware and software used in our products.

Prototyping

With our technologies, we guarantee high-quality, reliable prototypes tailored to our customers' needs.

- We quick check that the product development aligns with key expectations. Our state-of-the-art facilities include 3D printing, 5-axis CNC machining and laser cutting allowing us to create precise prototypes efficiently.

- We also operate a fully equipped model shop for low-volume series and provide rapid electronics prototyping to accelerate innovation.

Accelerating Innovation

- R&D Departments and Competence Center work with the best-in-class equipment including Mold Flow Analysis, FEA simulation, numerical-to-experimental correlation, and tolerance stack-up calculations, to optimize design and manufacturability.

- Our teams collaborate seamlessly to develop, prototype, test, and validate solutions using state-of-the-art reliability and validation services. By integrating advanced simulation and real-world testing, we accelerate product development while maintaining the highest industry standards.

Testing

Cebi’s advanced testing capabilities ensure the highest standards of quality, durability, and performance for our products.

- Our state-of-the-art laboratories conduct rigorous mechanical, environmental, thermal, and electrical tests, simulating real-world conditions to guarantee reliability.

- With decades of expertise, we provide extensive validation processes, endurance testing, and compliance assessments tailored to industry and OEM requirements.