Cebi’s P+T Sensors: Innovation Built on Experience

Cebi’s P+T Sensors: Innovation Built on Experience

A History Rooted in Adaptation and Vision

Cebi’s expertise in pressure and temperature measurement traces back to the late 1990s, when our Spanish facility was producing oil pressure switches for combustion engines. Recognizing the growing demand for more advanced sensing, we began exploring capacitive pressure sensors, then a pioneering technology.

By the late 2000s, the automotive sector was undergoing rapid change. Combined pressure and temperature (P+T) sensors were entering fuel systems in high-efficiency diesel engines, displacing conventional solutions. At the same time, new environmental regulations accelerated the adoption of variable valve timing systems, which required accurate and real-time oil pressure feedback.

A two-fold technical challenge

On the one hand, it was necessary to master the thick-film-on-alumina printing technology, usually employed to manufacture hybrid circuits. And also apply it to the manufacture of a ceramic capacitive pressure transducer, an especially difficult device, which involves dealing with sub-micron dimensions and sub-picofarad capacitance values. This required materials, machinery and processes never previously used at Cebi.

On the other hand, it was necessary to design a high accuracy capacitance-to-voltage signal conditioning electronics, capable of reading out the ceramic capacitive transducer and outputting a usable signal under various protocols (analog, LIN, SENT). This required a multi-year-long effort combining reverse-engineering of existing designs, often guessing the secrets hidden behind the patents of industry leaders such as Sensata or Robert Bosch combined with quite a lot of forward thinking.

These shifts drove Cebi to invest in a multi-million-euro development program focused on ceramic capacitive technology. The main challenge? To pack what was initially an Eurocard-sized prototype into a sensor envelope the size of a typical oil pressure switch. Our teams steadily miniaturized the design, achieving today’s highly compact and robust P+T sensor platform.

This progression has not only preserved Cebi’s competitiveness but has also reinforced our role as an innovator in critical sensing technologies.

Technology at the Core: Robust, Accurate, and Intelligent

At the heart of Cebi’s P+T sensors is a ceramic capacitive absolute pressure transducer, designed and manufactured entirely in-house. Unlike relative sensors, which are sensitive to environmental factors, the absolute design ensures stability and accuracy across harsh automotive environments.

The technology relies on two alumina ceramic plates sealed hermetically with a glass bond. When pressure is applied, one of the plates deforms, resulting in a change of capacitance that is translated to a pressure signal by the integrated electronics. This principle, combined with carefully engineered package to minimize stray fields, delivers reliable and precise measurement.

Complementing the pressure sensing element, Cebi integrates a high-precision NTC thermistor for fast-response temperature monitoring. The advanced electronics - relied initially on commercial microcontrollers and is now evolving toward a proprietary ASIC solution.

Key features include:

- Operating range from -40°C to +160°C.

- Pressure ranges scalable from 10 bar to over 100 bar by adapting membrane thickness.

- 100% digital calibration at end-of-line for guaranteed accuracy.

- Advanced signal conditioners with case-by-case customization, ensuring compatibility with customer systems.

- AEC-Q100 qualified ASICs for robust automotive-grade performance.

This marriage of ceramic technology and advanced electronics enables high accuracy,

robust resistance to environmental challenges. The result is a sensor platform that combines reliability with adaptability; exactly what modern mobility demands.

Markets and Applications: Serving a Changing Mobility Landscape

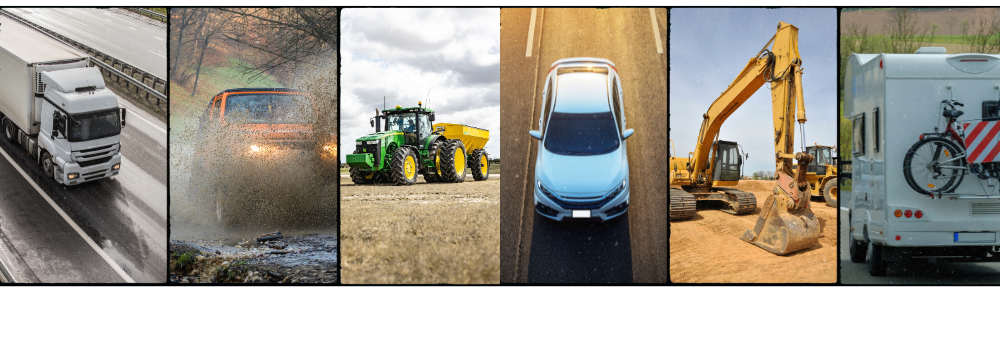

Cebi’s P+T sensors are deployed in a wide array of automotive, industrial, and off-road applications, where reliability and precision are mission-critical.

The proprietary ASIC is, after the ceramic capacitive transducer, the second access barrier to the technology (and the market). All key competitors have such an ASIC in their designs, and no equivalent integrated circuit is available on the free market which can enable the functionalities provided by those very advanced ASIC’s.

In particular, the capacitance to voltage converter is key to sensor performance and is a very well-guarded secret. Cebi had to go by trial and error, reading between the lines of the relevant patents, creating its own design and progressively refining it up to the point of reaching the required performance (and size). The ASIC also makes it possible to pack into a small-size sensor, in a configurable way, the interface communication protocols most often used by the automotive OEM’s, which again is a feature not found in any off-the-shelf, commercially available, integrated circuits.

Automotive Powertrain

- Engine oil and transmission systems: Providing accurate pressure and temperature data to optimize lubrication, reduce emissions, and extend component life.

- E-axle and hybrid drives: Supporting new electric powertrain architectures with robust sensing for hydraulic control and thermal management.

Thermal Management & Fuel Systems

- HVAC refrigerants: Ensuring efficient and safe operation of climate control systems under high pressure.

- Fuel and injection systems: Enabling precise monitoring in both conventional and alternative fuel applications. Start&Stop systems rank high in this field of application.

Beyond Passenger Cars

- Heavy-duty trucks, agricultural machinery, and off-road vehicles: Delivering dependable sensing performance in harsh environments where uptime and durability are essential.

Recent production awards underscore this versatility: one program supports a French carmaker EP6 gasoline engine produced in the U.S., while another equips electric axle hydraulic systems for trucks, showcasing Cebi’s role in both legacy and next-generation mobility platforms.

Conclusion: Innovation That Endures

From humble beginnings in oil pressure switches to today’s high-tech PT sensors, Cebi’s story reflects a mindset of innovation, resilience, and forward-looking engineering. By mastering ceramic capacitive technology and integrating advanced electronics, Cebi is uniquely positioned to support customers in the shift toward cleaner, smarter, and more efficient mobility.

With every PT sensor delivered, we reaffirm our commitment to engineering excellence and market relevance, hallmarks of Cebi’s DNA for over half a century.