How We Work

In-house Automation

As part of our vertical integration strategy, many of our assembly lines are semi-automatic or fully automatic. This sophisticated level of automation enables us to:

- Provide flexibility within our production structure.

- Offer the possibility to produce just in time.

- Quickly turn around design changes that may be required.

Photo: brand-new project for a car roof rail 100% manufactured in-house at Cebi Brasil, from injection molding to assembly and quality control

The Power of our R&D

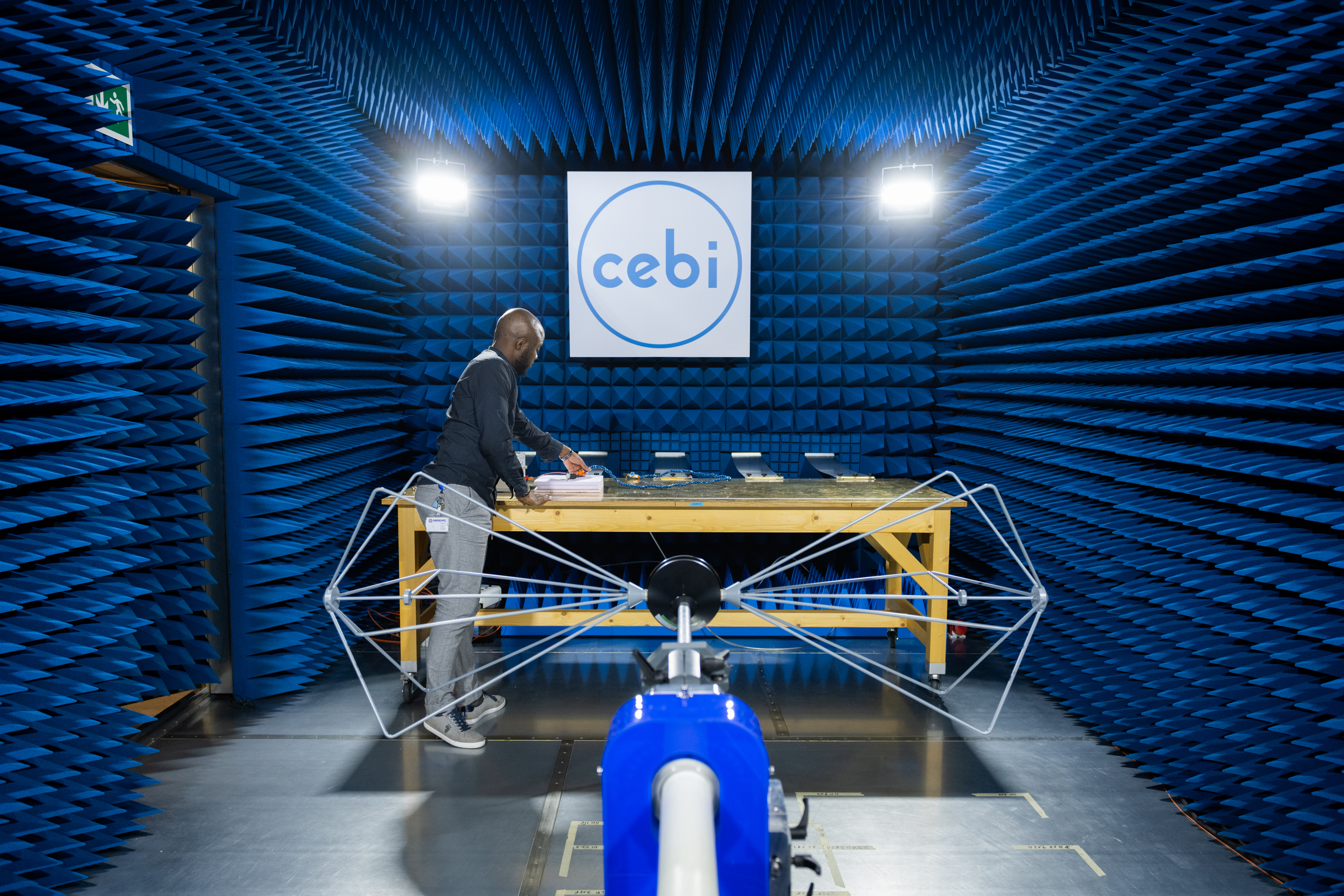

We are constantly testing and improving the quality of our products by investing in our R&D capabilities with:

- 7 R&D departments set-up in the world (Competence Centres).

- 260 experts fully dedicated to innovation and product enhancement across our plants.

- Our own Testing Laboratory infrastructure with state-of-the-art equipment.

Photo: Cebi Testing Services EMC Chamber

Quality First

All our production plants are in compliance with the following standards:

- ISO 9001: for comprehensive quality management

- IATF 16949: for automotive-specific quality management

- ISO 14001: for environmental management

These certifications underscore our commitment to delivering products of the highest quality while minimizing our environmental impact, ensuring that our manufacturing processes align with globally recognized industry standards.

Photo: With this label from the Swiss Private Sector Energy Agency, Cebi Micromotors Switzerland's products are compatible with 90% of existing markets in terms of energy obligations

Digital Manufacturing and Life Cycle Management

From design and prototyping to production and maintenance, we streamline and optimize the entire product lifecycle through digital processes supported by:

- A dedicated Industry 4.0 cluster since 2019 to design the digital factory of tomorrow.

- Connected production equipment through an in-house data analytics platform enabling us to asses our manufacturing operations in real-time.

- A cross-digital platform launched in 2022 enabling the digital integration of Cebi's product development and manufacturing processes throughout the Group.

Photo: In-house data analytics platform used in our production plants